GO GLOBAL

Aiming for World-Class FRP Technology

GO GLOBAL

Aiming for World-Class FRP Technology

2024/8/?? :

公式ホームページリニューアル

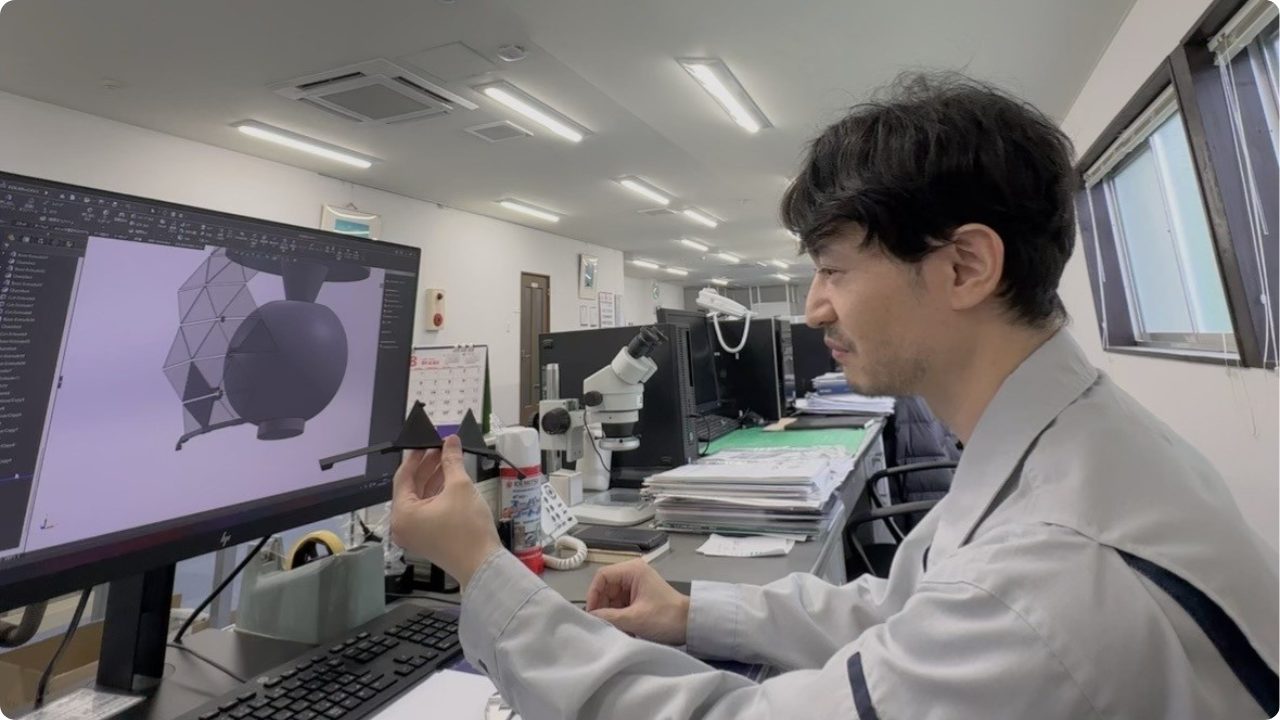

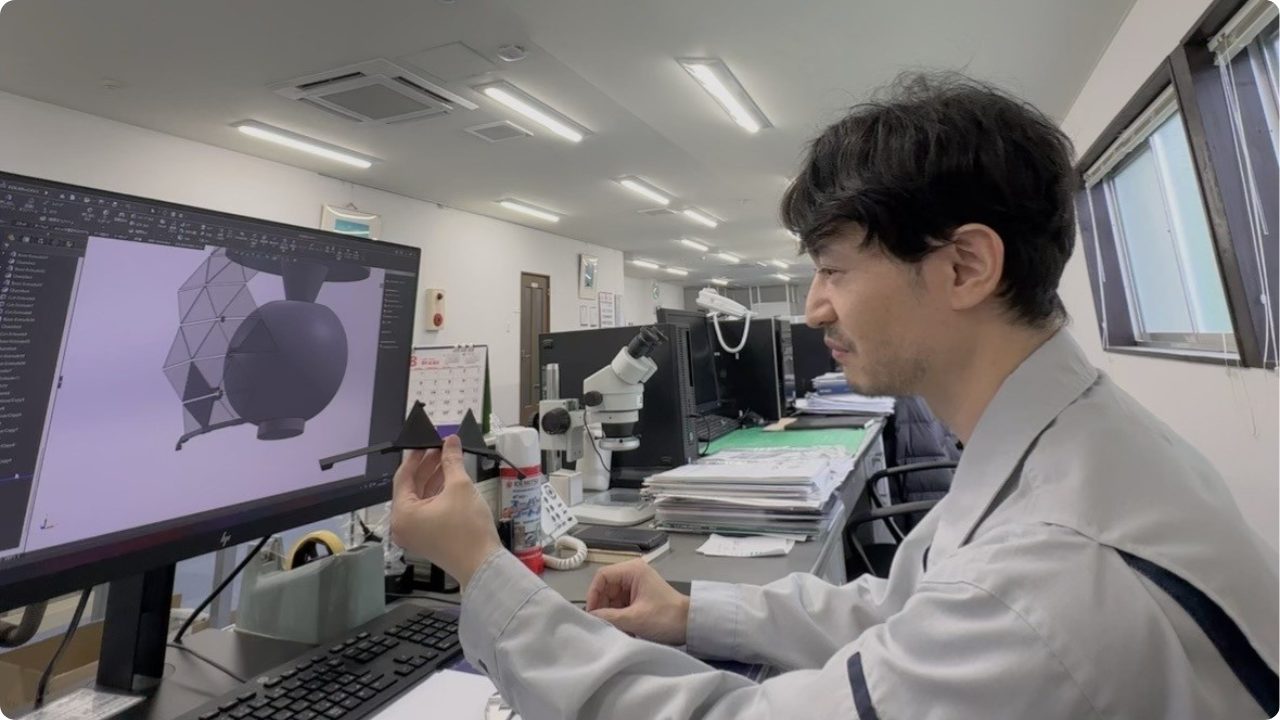

Professionals in FRP

We are a manufacturing company fundamentally based on the production of Fiber Reinforced Plastics (FRP).

We collaborate with our customers from the initial planning stage to determine how we can create products that realize their ideals.

Our strength lies in our ability to consistently handle every aspect of FRP manufacturing, from planning and prototyping to design, production, and mass production (including molding, painting, processing, and assembly).

Our specialized staff and craftsmen, who have mastered various manufacturing methods through years of experience, will surely meet all of our customers’ requirements.

Medical equipment

We manufacture parts for large medical equipment such as CT and MRI. Large medical equipment like CT and MRI comes equipped with about 20 cover parts, and the mutual engagement of the covers determines the quality of the product. Machining expertise with skilled manual tasks is required for the covers to maintain specified clearances between themselves without level differences. Moreover, we achieve even higher precision by combining the use of jigs with machining. We engage in processing from mold-making to prototyping and mass-production. We also we apply paint and assemble electronics in mass production. Integrated production is used to achieve shorter lead times and cut costs.

Housing and architectural equipment

The housing and architectural equipment industry has particular needs for coloring and color development, along with chemical resistance. We will make optimal suggestions in response to the design that you envisage and the environment where you will be using your product.Our Clerical Department has an Environmental Management Secretariat, which quickly and appropriately satisfies your requirements regarding chemical substances. We can satisfy regulations in Japan, and also environmental regulations abroad.

Aeronautic and sporting fields

We manufacture very lightweight aircraft, sea kayaks, and other products. Equipment in sporting fields is required to remain strong while being very highly lightweight to allow contestants to maximize their performance. Vacuum molding is one of the molding processes for maximizing strength characteristics. We have been upgrading our technology through the production of ultra-light aircraft which we have been developing in industry-university collaboration.

Natural energy fields

We apply the knowledge and experience that we have cultivated with medical equipment parts, corrosion-proof tanks, and other large fiber-reinforced plastics (FRP) to manufacture FRP parts for wind power generation plants.The difficulty with large FRP molds is that the base material tends to shrink, making it hard to secure engagement precision with the opposite parts. This is why we always bear in mind the importance of manufacturing molds in expectation of base material shrinkage and make suggestions on product structure from the standpoint of FRP design.

Chemical fields

We manufacture covers for electron microscope tables, corrosion-proof tanks, and the like.Chemical fields require the maintenance of high strength, and also precise design, development, and manufacturing to satisfy requirements for chemical resistance, low thermal conductivity, and other characteristics. We can make use of our many years of experience and track record to confidently engage in developing products for chemical purposes as well.

Natural Energy Facilities

We provide maintenance support for wind power generation facilities, leveraging the knowledge and experience gained through manufacturing and installation support of FRP components for wind power equipment. The government’s “Green Growth Strategy,” which aims to achieve net-zero greenhouse gas emissions by 2050, plans to increase offshore wind power generation capacity to a maximum of 45 million kilowatts by 2040, equivalent to 45 nuclear power plants. We must definitely achieve the government’s goals and leave a safe and clean global environment for the next generation. Our strength in FRP repair technology is being utilized for appropriate and rapid treatment of wear and tear caused by erosion (erosive action when wind, rain, ice, snow, small animals, etc. collide) on blades rotating at speeds over 200 km/h.

Medical equipment

We manufacture parts for large medical equipment such as CT and MRI. Large medical equipment like CT and MRI comes equipped with about 20 cover parts, and the mutual engagement of the covers determines the quality of the product. Machining expertise with skilled manual tasks is required for the covers to maintain specified clearances between themselves without level differences. Moreover, we achieve even higher precision by combining the use of jigs with machining. We engage in processing from mold-making to prototyping and mass-production. We also we apply paint and assemble electronics in mass production. Integrated production is used to achieve shorter lead times and cut costs.

Housing and architectural equipment

The housing and architectural equipment industry has particular needs for coloring and color development, along with chemical resistance. We will make optimal suggestions in response to the design that you envisage and the environment where you will be using your product.Our Clerical Department has an Environmental Management Secretariat, which quickly and appropriately satisfies your requirements regarding chemical substances. We can satisfy regulations in Japan, and also environmental regulations abroad.

Aeronautic and sporting fields

We manufacture very lightweight aircraft, sea kayaks, and other products. Equipment in sporting fields is required to remain strong while being very highly lightweight to allow contestants to maximize their performance. Vacuum molding is one of the molding processes for maximizing strength characteristics. We have been upgrading our technology through the production of ultra-light aircraft which we have been developing in industry-university collaboration.

Natural energy fields

We apply the knowledge and experience that we have cultivated with medical equipment parts, corrosion-proof tanks, and other large fiber-reinforced plastics (FRP) to manufacture FRP parts for wind power generation plants.The difficulty with large FRP molds is that the base material tends to shrink, making it hard to secure engagement precision with the opposite parts. This is why we always bear in mind the importance of manufacturing molds in expectation of base material shrinkage and make suggestions on product structure from the standpoint of FRP design.

Chemical fields

We manufacture covers for electron microscope tables, corrosion-proof tanks, and the like.Chemical fields require the maintenance of high strength, and also precise design, development, and manufacturing to satisfy requirements for chemical resistance, low thermal conductivity, and other characteristics. We can make use of our many years of experience and track record to confidently engage in developing products for chemical purposes as well.

Natural Energy Facilities

We provide maintenance support for wind power generation facilities, leveraging the knowledge and experience gained through manufacturing and installation support of FRP components for wind power equipment. The government’s “Green Growth Strategy,” which aims to achieve net-zero greenhouse gas emissions by 2050, plans to increase offshore wind power generation capacity to a maximum of 45 million kilowatts by 2040, equivalent to 45 nuclear power plants. We must definitely achieve the government’s goals and leave a safe and clean global environment for the next generation. Our strength in FRP repair technology is being utilized for appropriate and rapid treatment of wear and tear caused by erosion (erosive action when wind, rain, ice, snow, small animals, etc. collide) on blades rotating at speeds over 200 km/h.

Globally Expanding Manufacturing Line

To accommodate global demands and enable mass production, JON72 has factories both domestically and overseas.

“The world’s most wonderful products,” “The world’s most efficient production,” “The world’s happiest,” “The world’s most environmentally friendly FRP products” – these are the world-class standards we aim for.